EverClean

The Always Clean Solution for Ship Hull Maintenance

Robotic Revolution

EverClean uses proprietary robot technology as the enabling factor to scale a safe, efficient, and intelligent solution to the age-old problem of biofouling on ships in a fleet.

With EverClean, we offer vessel owners a revolutionary new way to manage their fleets’ hull performance and condition. By maintaining an always clean hull, we change the entire dynamic around hull maintenance—from an inefficient, episodic, or reactionary model to an always clean intelligence-based model.

EverClean, and the concept of an always clean hull offered by Greensea IQ, is the first robotics-as-a-service subscription for ship hull cleaning of its kind. It stands in stark contrast with the inherently harsher and larger manually operated or diver-assisted reactive systems currently being used today.

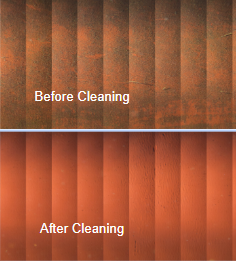

The EverClean robots carry out cleaning operations with unmatched precision, resulting in minimal repetition and accurate data collection to deliver a hull condition report after each service; they offer a distinct “always clean hull” maintenance solution.

EverClean Delivers Value

Fuel Savings

- In a recent analysis utilizing the ISO 19030 standard of one of our customer’s vessels, EverClean achieved a 20% fuel savings in the 8 months the vessel was regularly serviced. We believe customers will save between 5% – 20% of fuel with regular servicing

- 2022 customers averaged 90% 30-day ROIs

Carbon Reduction

- Current EverClean customers reduced emissions an average of 6.4% with higher results on some vessels.

- Significant financial savings potential for reducing emissions and receiving a passing CII rating

Maintenance

- Minimized dry dock intervals with intelligence-based planning

- Avoid heavy fouling and harsher cleaning methods while extending coating life with continuous maintenance

Fleet Readiness

- Extended range on single fueling (simplified logistics)

- Minimize downtime by improving maintenance decisions through collected EverClean IQ

Biosecurity

- By habitually removing slime, hard macrofouling is denied a biologically conducive place to settle and thrive

- EverClean’s approach is backed by academic research

EverClean Performance

The most straightforward way to reduce emissions is to reduce fuel consumption. Fuel consumption can be reduced through efficient operations, including ensuring the hull is as hydrodynamically efficient as possible.

Once built and painted, a ship’s hull needs to be kept as clean as possible. Any growth on the hull will have a negative impact on performance. A recent report published by the IMO’s Glofouling Partnership has indicated that a very thin layer of slime (approx. 0.5 mm thick) covering 50% of a hull can increase emissions by as much as 20% to 25%.

Simply by removing biofouling as a variable and keeping it off, EverClean delivers a new flattened performance baseline, so you can stop monitoring noisy data searching for key events in perpetually normalizing data sets and instead discover small issues before they become big problems.

Invasive Species Control

Equally significant is the impact of biofouling and the potential transport of invasive species from port to port. The Australian biofouling management requirements stipulate that incoming ships must address biofouling through proof of a biofouling management plan, having cleaned the vessel of all biofouling within the past 30 days, or the use of an Australian-approved alternative biofouling control method.

Although Australia is in the lead for published guidance, the IMO’s Glofouling Partnerships Project is working on a global scale, raising awareness and driving regulations to help protect the world maritime environment.

EverClean’s always clean approach will support compliance with these, and similar, regulations. Over time, the EverClean ship hull cleaning service will gather aggregate data to create a predictive fouling and a biosecurity model, which benefits the global community by providing valuable insights into the prevention of fouling and the maintenance of biosecurity standards.

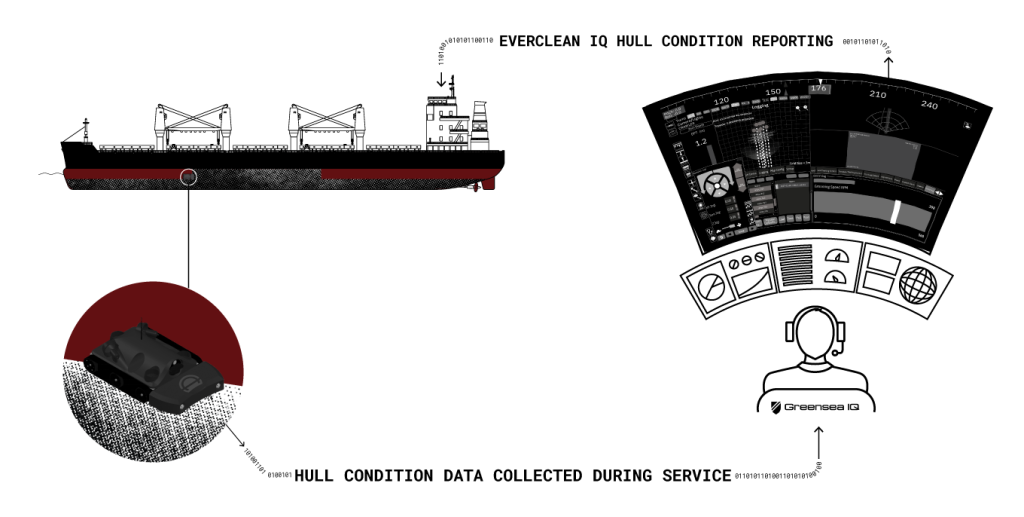

EverClean IQ

Understand the Impact of Maintaining an Always Clean Hull.

Delivered as part of the EverClean service, EverClean IQ is our groundbreaking data-reporting solution designed to assist commercial vessel owners in understanding the general health of their hulls based on the data collected during routine EverClean ship hull cleaning service.

As the EverClean IQ platform evolves, our users will be able to purchase additional detailed data sets collected during cleaning operations that can provide a high level of change detection and inform very accurate predictive analytics.

EverClean IQ will enable you to make more accurate decisions about preventative maintenance and repairs pre-dry-dock planning and provide a validation tool to ensure clean hulls for biosecurity regulations—all saving you time and money.

Start reducing emissions and saving on fuel now! Contact us about setting up EverClean service for your fleet.